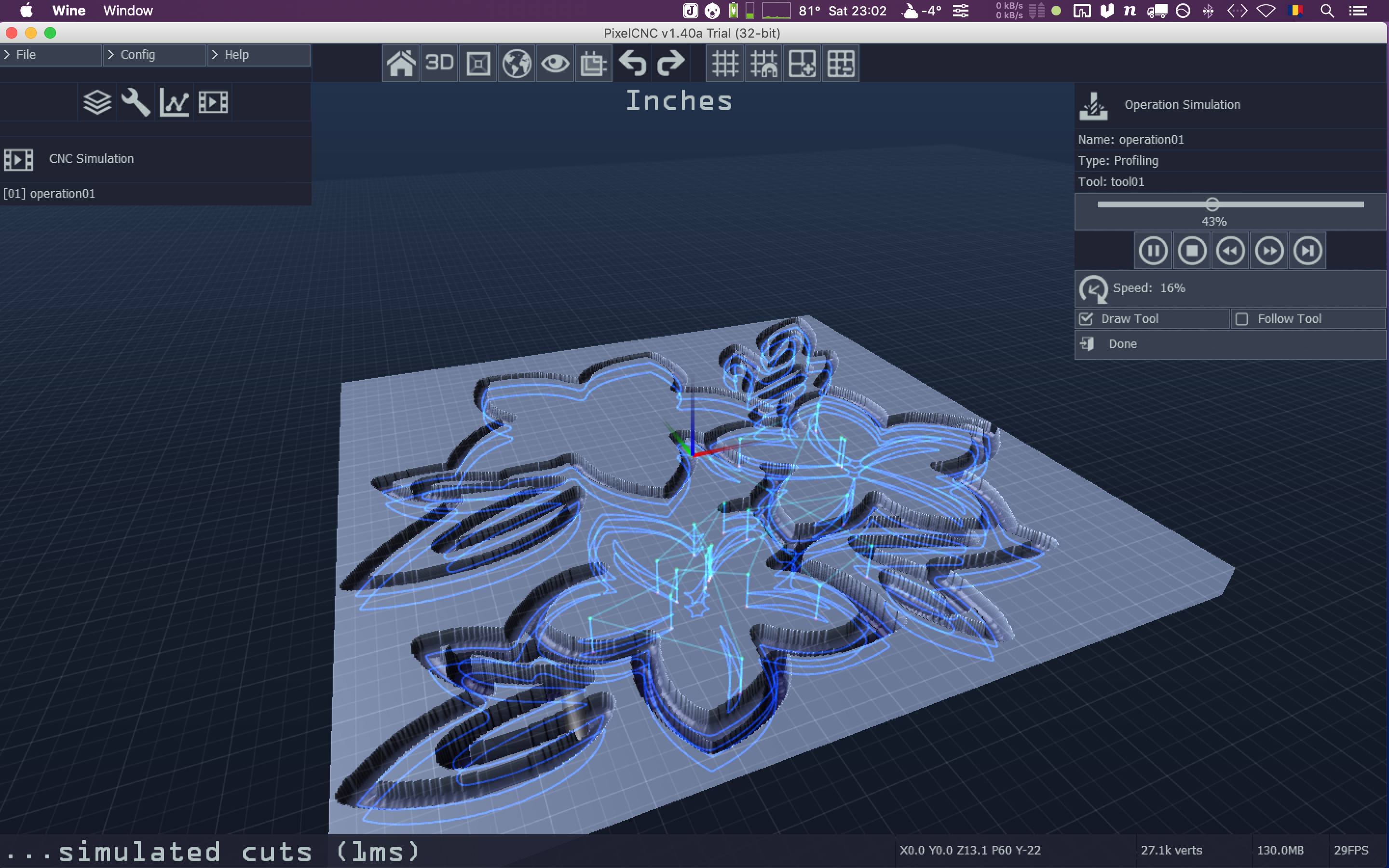

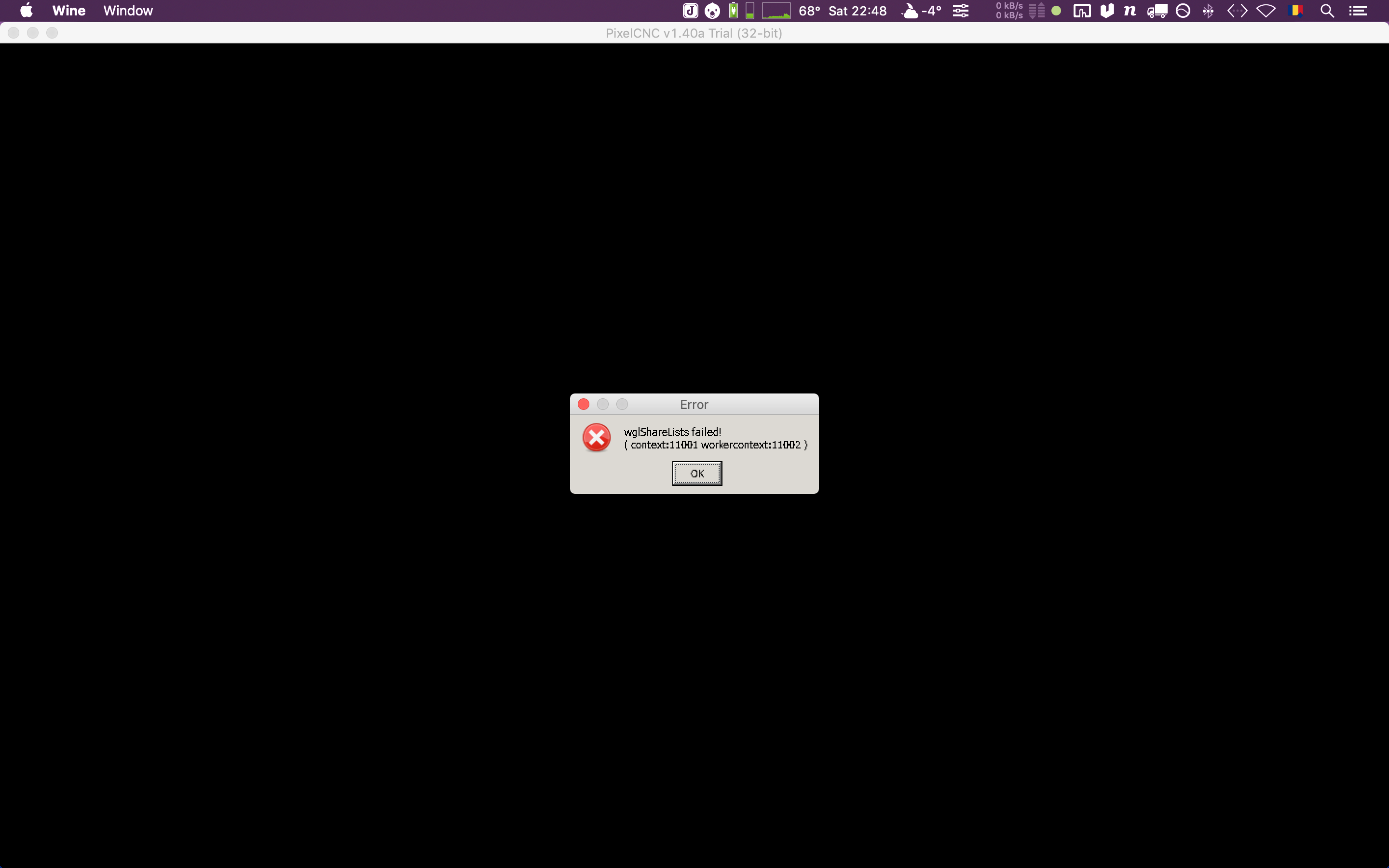

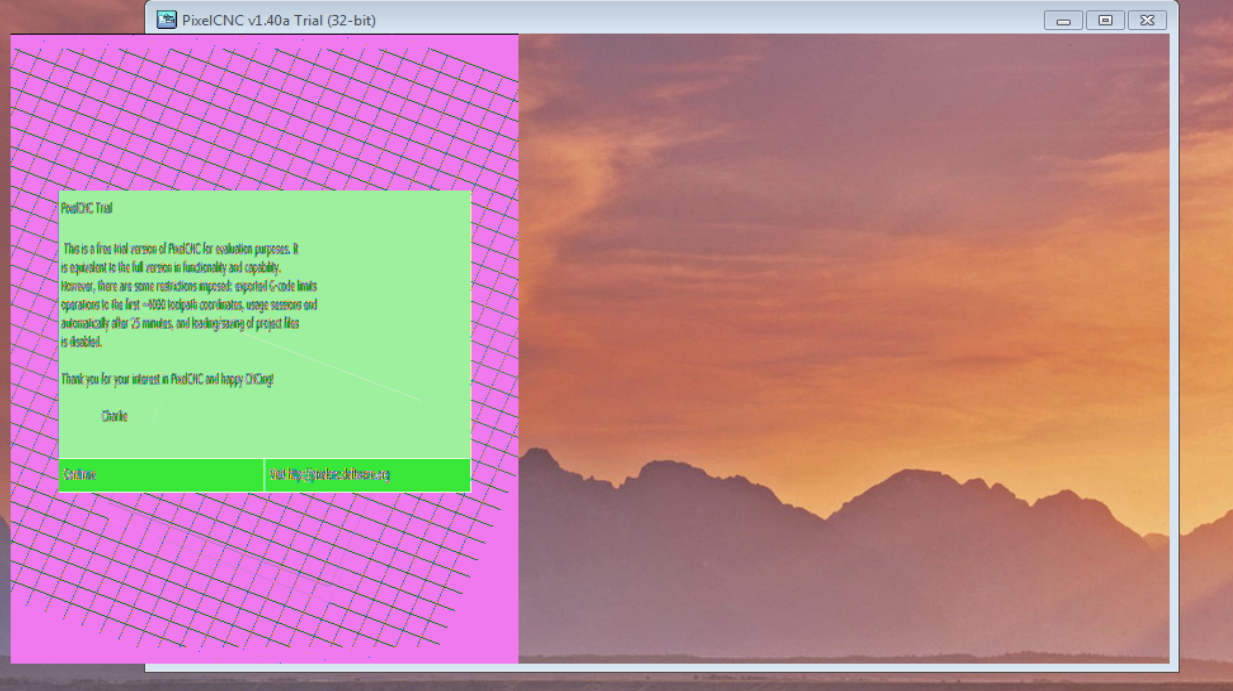

I agree that a native Linux version will be the best. Myself I just experimented to see if I can run PixelCNC on my Linux and MacOS Machines. I don't use Windows from some good years now.

Dacicusan

Recent community posts

Actually this project it gives me hopes that I will see innovation in the field of CAM software for hobbyist CNC makers and alike. Nothing really interesting came out in this field for so many years now. Vectric stoped to innovate some ten years ago. From then they are just reinventing the wheel, any "major update" it is just a mere bunch of bug-fixes and tiny improvements and nothing more. ArtCAM it is just changing the owner every few years, adding nothing to the table but only price increases on licensing side. FreeCAD path it is still far away for real work, Fusion360 it is only subscription/cloud based, Autodesk being recognised as one of the worst and the most untrusty software company in the planet, and the other CAM projects are or overpriced or not very competitive, like CamBam struggling to take the version 1.0 for a few years now, etc. DeskProto seems to be the only software who is improving, they are preparing a MAC and Linux version, testing myself the beta right now, but their 5axis capabilities are limited to "trunion" machines, and the toolpath-simulation it is the worst I ever seen.

Deftware, please take into account that all the hobby CNC softwares are offering a lot of options for cabinet makers, because this is how the market is. Majority of the CNC "hobby" and "semi-pro" owners are do making furniture and cabinets, so it is logic that all this CAM softwares to offer tools to easily take the design to CNC machine. The "artistic" part is only a fraction of the whole market, and any CNC owner wants a single software tool to do all the job. Your software seems good on the artistic side, but right now offers nothing for furniture production, which is a pity.

Once this project will become more popular, I think you will have enough income to dedicate only to programming this wonderful software. I discovered this project by mistake, was just a short mention into a forum, nowhere else I found references before. Definitely this project needs more marketing because have great potential.

I also intend to build a CNC machine with a 4th rotating axis (wood lathe) and the main head to be 5axis driven. Maybe my first machine will be only 3axis and the 4th for lathe, but second one certainly will be a 5axis one. If you need 5axis algorithms you can check the http://www.5axismaker.com project. It is a Rhino-Grasshopper definition that can generate 5axis gcode for CNC machines.

As I read on the manual, you have the intention to add DXF import support into PixelCNC. This is great news for me, and I need to know if it is possible to add also a "Toolpath Template" that will translate the DXF layers into automatic toolpath generation?

I need to explain better this concept, hopefully it is not so difficult to grasp.

A lot of CAM softwares, including WoodWop, AlphaCAM, Aspire, ArtCAM, etc. have this option. Basically needs to define a configuration file for the imported DXFs, so the software translates and interpret the naming of the layers from the DXF file to automatically associate specific layers to specific mechanisation operations. For example, let's say I do have a layer into my DXF file, called "P6_T5". I want, when imported the DXF file into PixelCNC to create a new layer called "P6_T5" and automatically associate that layer to a Pocket operation, 6mm deep and to use the tool number 5 to create the tool-path. Or, "C10_T4" to create an outside contour, 10mm deep using the tool nr. 4.

This option it is very useful for cabinet makers and sign-makers as it is making the overall workflow more automatic.

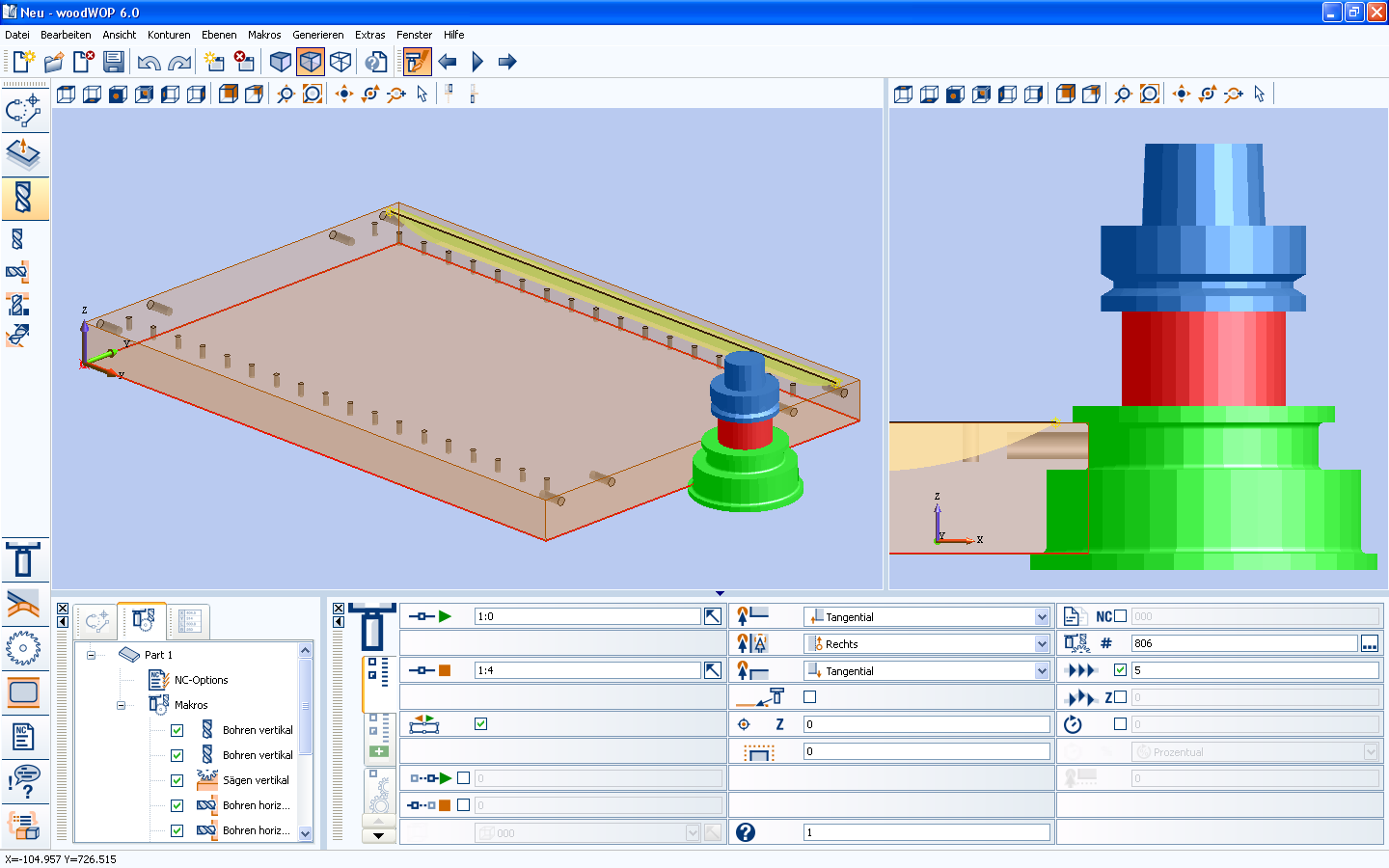

A short demonstration of DXF workflow between AutoCAD and WoodWop:

ToolPath Templates in ArtCAM:

ToolPath Templates in Vectric software:

Yes, hopefully that will do the job.

But as I can see you have support for STL files:

Stereolithography, binary (.STL)

(COMING SOON) Sterelithography, ASCII (.STL)

(COMING SOON) Wavefront Object, binary/ASCII (.OBJ)

So, will be easy to create a template with half of the object in one CAM program and the other half into another CAM program, using some reference holes and tabs to be able to flip perfectly the workpiece on table between the two sides mechanisation.

Hi Defware. Thank you for reply. I do have more than a decade of experience working professionaly with different kind of CNC machines and as furniture designer. Hopefuly the next year I will be able to have my own hobby CNC machine. For this reason I am interested in PixelCNC. I already purchased the controller from the PlanetCNC, but still I need the motors and the rails.

Back to topic, will be useful to have an option to import a DXF shape and use that shape to define the profile of a new tool.

I used CAM softwares like WoodWop, where iI can import a profile from a DXF file and use that profile to create a new tool that will be visualized into simulations. Something like this:

Into the examples bellow, it is showing how to achieve the same thing into the Vectric softwares, here it is called "Form Tools":

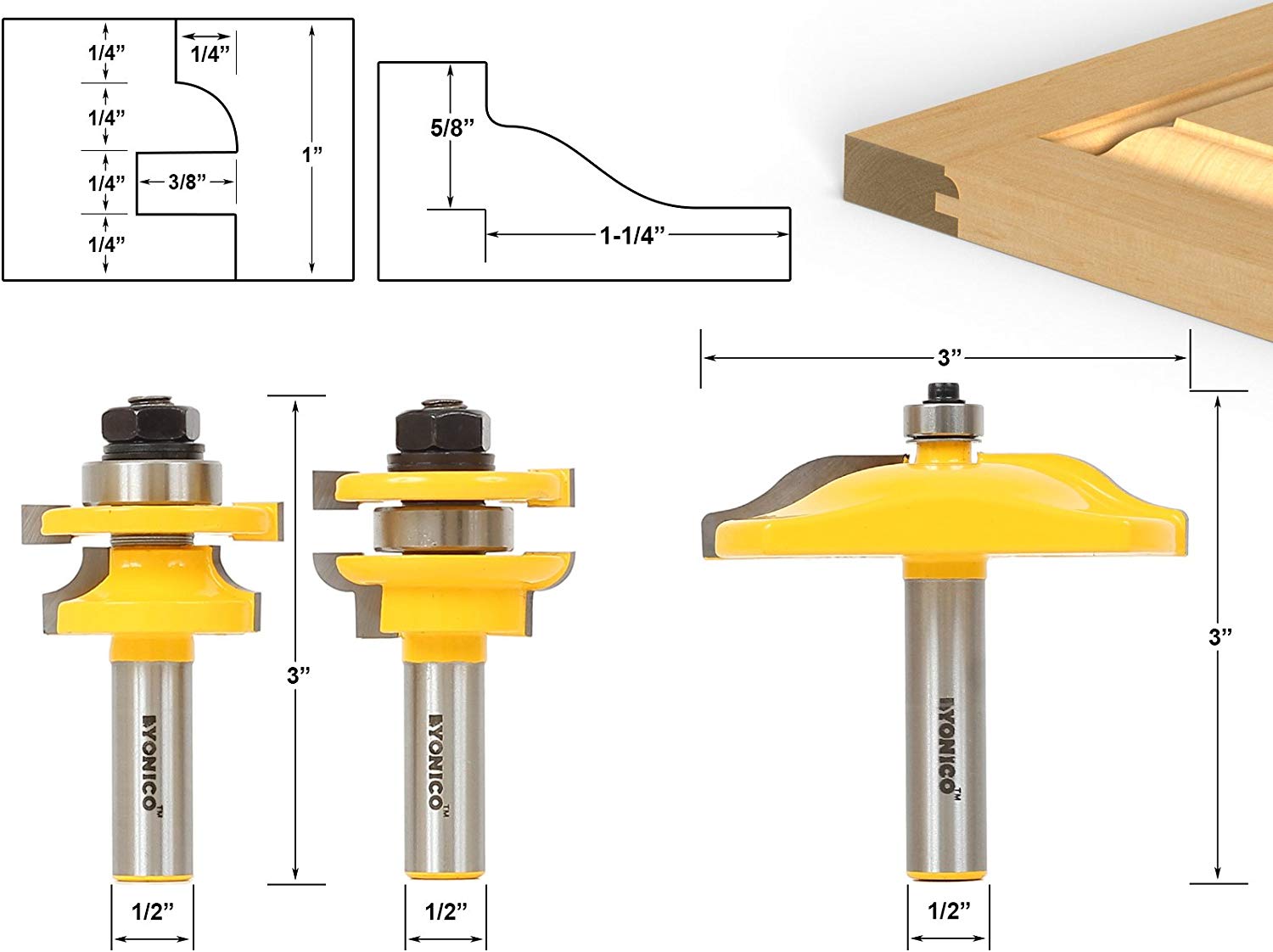

With my machine I do intend to do some cabinet profiled doors and different profiled joinery element, and I will need to use a lot of different profile bits like this ones:

If you need further informations, please let me know.

Will be great to have an option to define a custom shape for the cutting tool. Another great feature would be an option to see the actual toolholder in simulation mode. Sometimes I run programs to the limit, and I need to detect eventual clashes between the toolholder and the working material. This two features will be very helpful to have.

Hi. I am interested to know if this software will have the capability to create two sides machining code? Please check this video for a better explanation: [Vectric V8 Tutorials - 2 Sided Machining](Vectric V8 Tutorials - 2 Sided Machining)